Shaft Processes in a Blast Furnace

Formation and reduction of Wustite in an ore particle

Abstract

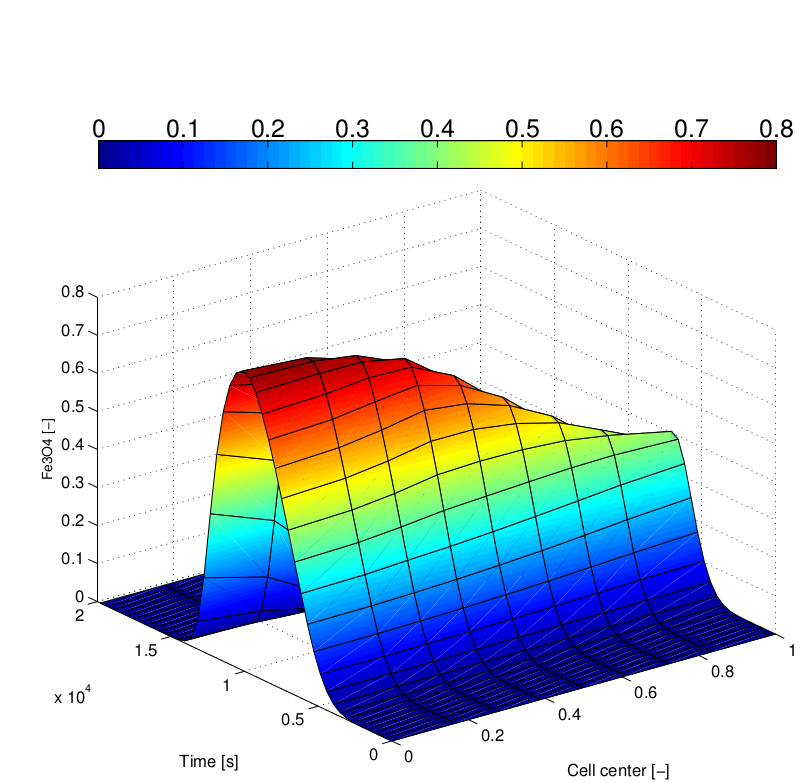

The objectives are to describe the reaction of ore particles within the surrounding reducing gas phase in the upper shaft of a blast furnace. Indirect reduction of iron oxides is addressed by a thermodynamically consistent equilibrium reactions of reduction-oxidation reactions. The particle model resolves accurately radial gradients of both species an temperature and therefore, omits rigorous assumptions or mathematical approximations to a specific experimental set-up. Hence, these qualities allow application of indirect reduction to the packed bed of the shaft of a blast furnace. Depending on the local conditions e.g. temperature and composition of the gas phase, each particle of the packed bed is subject to spatially and temporal boundary conditions that determine the thermodynamic state e.g. reduction degree of each particle and thus, the all-over behaviour of the shaft.

People

- Partners: CRM Group, Belgium;

- Contact: Prof.-Dr.-Ing. B. Peters

Funding

|

This research is supported by the University of Luxembourg. |

|

This research is in the framework of the project "DigitalTwin", supported by the programme: Investissement pour la competitivite et emploi - European Regional Development Fund (Grant agreement: 2016-01-002-06). |