Raceway of Blast Furnace

Raceway of a blast furnace

Abstract

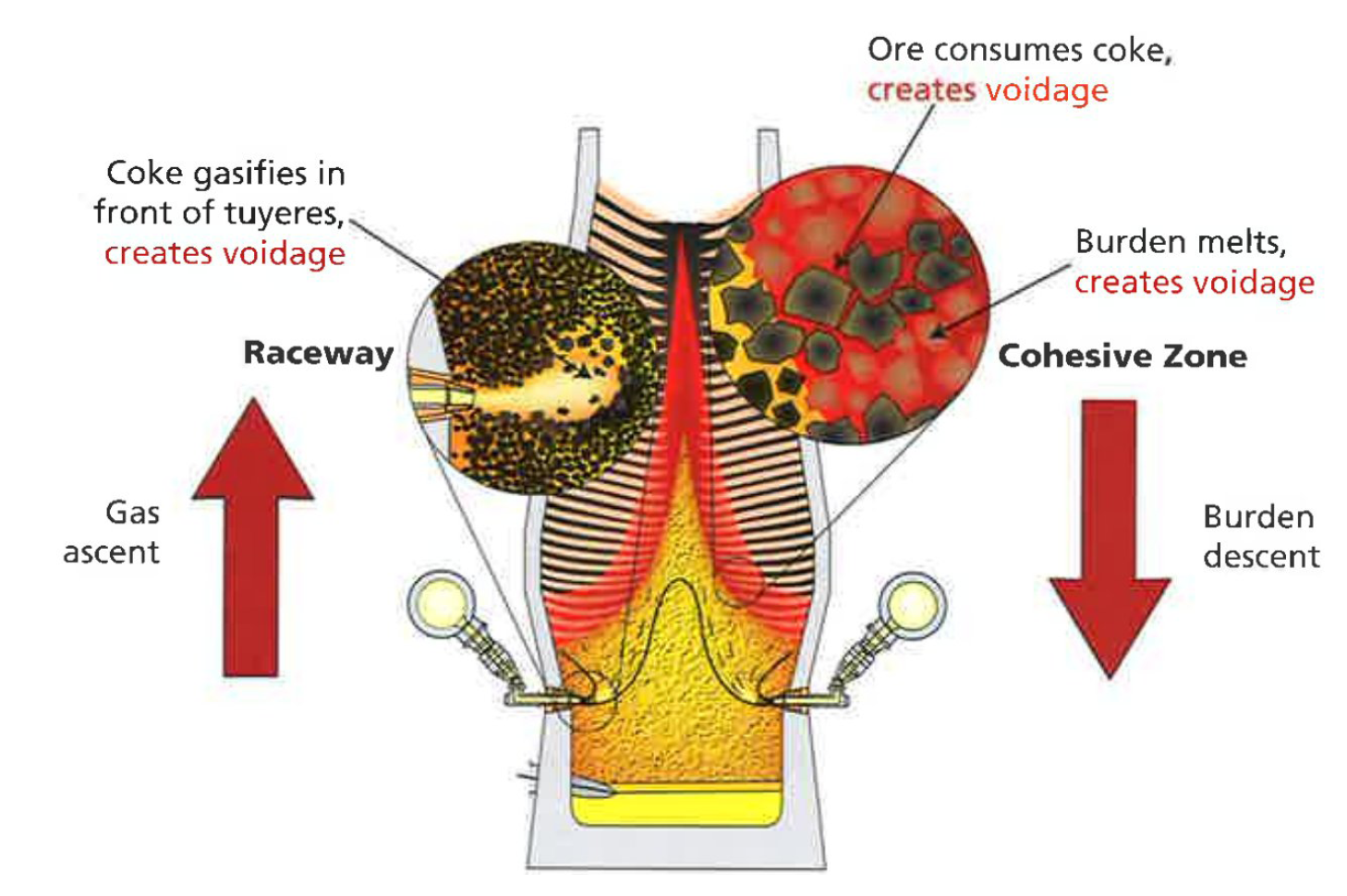

The objective of this research project is to analyse the raceway of a blats furnace. A hot gas jet is injected horizontally into a packed bed of coke particles at the lower part of a blast furnace where it forms a cavity called raceway. The hot gas has a temperature of app. 2000-2200° C and is injected through the tuyeres with a velocity of app. 220-250 m/s shown in the figure below. Under these conditions, entrained particles are driven by a fast stream of blast gas into a packed bed, forcing coke particles within the bed upwards and back around into the gas flow. In the raceway the carbon from the coke or other auxiliary fuels for instance the pulverized coal (PC) reacts with the oxygen to provide heat and to produce carbon monoxide, which act as gaseous reducing agent. The Extended Discrete Element Method (XDEM) is applied to describe both thermodynamics and motion of coke particles that undergo a vigorous interaction with the reacting gasphase represented by a multi-phase flow solver based on the OpenFoam platform. The flow rate and vertical velocity of the gas phase, which are dependent on the gas permeability are important to reach a high efficiency.

People

- Partners: CRM Group, Belgium;

- Contact: Prof.-Dr.-Ing. B. Peters

Funding

|

This research is supported by the University of Luxembourg. |

|

This research is in the framework of the project "DigitalTwin", supported by the programme: Investissement pour la competitivite et emploi - European Regional Development Fund (Grant agreement: 2016-01-002-06). |